With Lonestar ICG , experience the power of reliable and efficient maintenance.

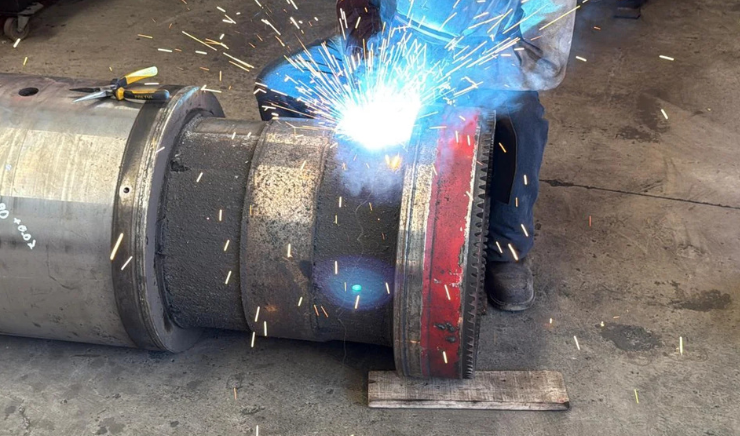

Field Service

Treatment of hydraulic oils, thermal oils, and phosphate esters

General oil recovery for efficient reuse

Professional cleaning of oil tanks

Chemical cleaning of pipes, systems, and oil coolers

Transfer of 200 to 500,000 liters of various oils

Complete diagnostics for hydraulic and lubrication systems